This topic explores how metal roll forming machine enable precise and accurate engineering in the manufacturing process. It can discuss the advanced technology and precision control mechanisms used in these machines, highlighting their ability to produce complex shapes, tight tolerances, and consistent results.

The discussion covers several important aspects of metal roll forming processes, highlighting the advancements in technology, precision control mechanisms, quality assurance, and product customization capabilities. These factors have played a crucial role in improving the efficiency and accuracy of metal roll forming machine, leading to the production of high-quality components with tight tolerances and complex shapes.

List of Table:

· Advanced Technology in Metal Roll Forming Machine

· Complex Shapes and Tight Tolerances

· Quality Assurance and Compliance Standards

· Enhancing Product Customization Capabilities

Advanced Technology in Metal Roll Forming Machine

Metal roll forming machine have undergone a remarkable evolution in terms of precision engineering, largely driven by advancements in technology. This progression has significantly enhanced the precision control mechanisms employed in these machines, ensuring unparalleled accuracy and repeatability in the manufacturing process.

Evolution of Precision Control Mechanisms

The evolution of precision control mechanisms in metal roll forming machine represents a pivotal shift towards achieving micron-level accuracy and consistency. Modern roll forming systems are equipped with advanced servo-driven components and sophisticated feedback loops, allowing for real-time adjustments and precise control over critical parameters such as material feed rates, roll pressures, and forming speeds. These precision control mechanisms have revolutionized the manufacturing landscape, enabling the production of highly complex geometries with minimal tolerance variations.

Integration of Computer-Aided Design (CAD) Systems

The seamless integration of Computer-Aided Design (CAD) systems into metal roll forming processes has ushered in a new era of precision engineering. CAD software enables engineers to meticulously design intricate profiles and geometries with absolute precision, taking into account material characteristics, forming constraints, and end-product requirements. By directly interfacing with the roll forming equipment, CAD systems ensure that the envisioned designs are translated into tangible, high-precision components, thereby minimizing errors and optimizing the manufacturing workflow.

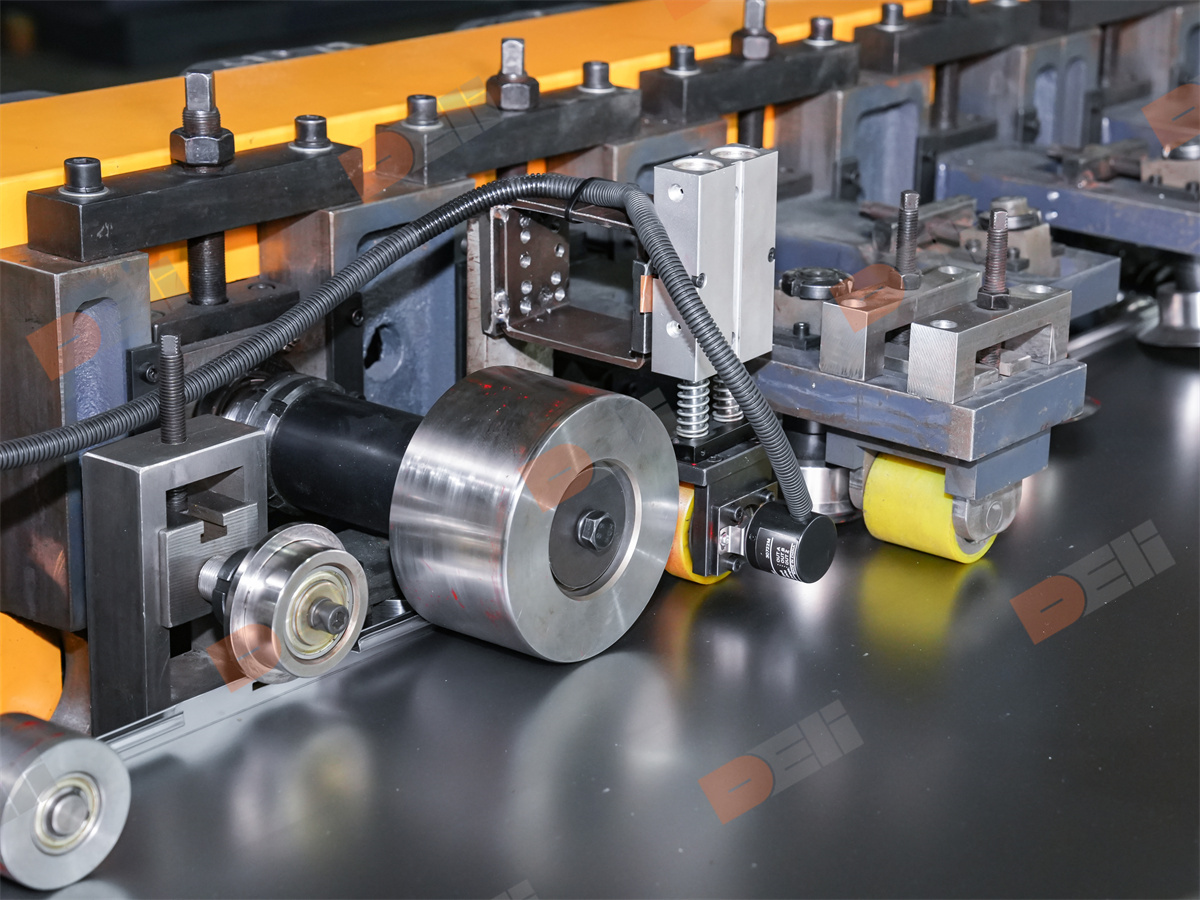

Utilizing High-Performance Tooling and Die Design

The utilization of high-performance tooling and die design is instrumental in achieving exceptional precision and dimensional accuracy in metal roll forming operations. Advanced tooling technologies, including CNC-machined dies, carbide tooling, and adaptive forming tools, have redefined the boundaries of what is achievable in roll forming. These cutting-edge solutions offer superior wear resistance, precise profile control, and rapid changeover capabilities, empowering manufacturers to meet the most demanding tolerances while maintaining high production throughput.

Complex Shapes and Tight Tolerances

Metal roll forming machines are well-suited for producing components with complex geometries and tight tolerances. Advanced tooling capabilities and precision control mechanisms enable manufacturers to produce intricate profiles and shapes with exceptional accuracy and consistency.

Forming Intricate Profiles with Precision

Metal roll forming machines utilize a variety of forming techniques to realize complex profiles with exceptional precision. Advanced servo-driven systems and feedback loops allow for real-time adjustments to critical parameters, ensuring that the intended geometry is achieved with minimal variation. In addition, specialized tooling such as CNC-machined dies and adaptive forming tools enable manufacturers to achieve accurate and repeatable results, even for the most complex profiles.

Achieving Consistent Wall Thickness and Dimensional Accuracy

Achieving consistent wall thickness and dimensional accuracy is paramount in metal roll forming processes. Advanced technology and sophisticated control mechanisms enable manufacturers to achieve micron-level precision and dimensional accuracy, even for components with varying wall thicknesses. This ensures that the end-product meets the required specifications and performs reliably in its intended application.

Ensuring Uniformity in Curved and Angled Sections

Producing uniform curved and angled sections is a key challenge in metal roll forming processes. However, advanced roll forming technologies enable manufacturers to form these sections with remarkable accuracy and repeatability. Computer-aided design (CAD) software allows for precise calculation of the material flow and stretch needed to form curved and angled sections, while advanced servo-driven systems and feedback loops ensure that the formed sections are uniform and consistent.

Quality Assurance and Compliance Standards

Quality assurance and compliance with industry-specific standards are imperative in the realm of metal roll forming. Manufacturers employ a range of strategies and technologies to ensure that their products meet stringent quality requirements and adhere to internationally recognized standards.

Meeting Industry-Specific Quality Requirements

Different industries have specific quality requirements for the components used in their applications. Metal roll forming machines are designed to accommodate these industry-specific standards, whether it’s the automotive, aerospace, construction, or any other sector. Manufacturers employ advanced quality control processes to ensure that their products meet or exceed the stringent quality standards set by these industries. This includes the use of precision measurement tools, material testing, and adherence to specific material and performance specifications.

Adhering to International Standards and Certifications

Adherence to international standards and certifications is crucial for manufacturers seeking to demonstrate the quality and reliability of their products on a global scale. Metal roll forming companies often obtain certifications such as ISO 9001, which signifies compliance with international quality management standards, as well as industry-specific certifications such as ISO/TS 16949 for automotive applications. By adhering to these standards, manufacturers instill confidence in their customers regarding the quality and consistency of their products.

Implementing In-Line Inspection and Testing Protocols

To ensure the quality and integrity of the products, manufacturers implement robust in-line inspection and testing protocols within their roll forming processes. Advanced sensor technologies, non-destructive testing methods, and real-time inspection systems are integrated into the production line to detect and address any deviations from the specified quality parameters. These in-line inspection and testing protocols enable manufacturers to identify and rectify any defects or variations during the manufacturing process, ensuring that only high-quality components reach the end customer.

Enhancing Product Customization Capabilities

The evolution of metal roll forming technology has significantly enhanced product customization capabilities, allowing manufacturers to cater to diverse and evolving market demands. By leveraging flexible design approaches, variable geometry roll forming techniques, and quick changeover systems, manufacturers can efficiently produce customized components with unparalleled precision and efficiency.

Flexibility in Design and Profile Modifications

Metal roll forming machines offer a high degree of flexibility in accommodating design changes and profile modifications. Advanced computer-aided design (CAD) software enables engineers to swiftly adapt component designs, allowing for rapid prototyping and seamless integration of design alterations. This flexibility empowers manufacturers to respond swiftly to custom requirements, ensuring that the final products align precisely with the unique specifications of each customer.

Incorporating Variable Geometry Roll Forming Techniques

Variable geometry roll forming techniques enable the production of components with non-uniform cross-sections and varying geometries. By dynamically adjusting the roll forming process parameters, such as the inter-stand distances and roll contours, manufacturers can achieve precise control over the material flow, allowing for the seamless formation of complex geometries and profiles. This capability is pivotal in catering to the growing demand for customized components across diverse industries.

Integrating Quick Changeover Systems for Diverse Production Needs

The integration of quick changeover systems within metal roll forming lines is instrumental in facilitating rapid transitions between different product configurations. By employing modular tooling, automated adjustments, and intuitive setup procedures, manufacturers can minimize downtime associated with changeovers, thereby enhancing operational efficiency and responsiveness to diverse production needs. This agility enables manufacturers to efficiently address varying customer demands while optimizing production throughput.