Product Description

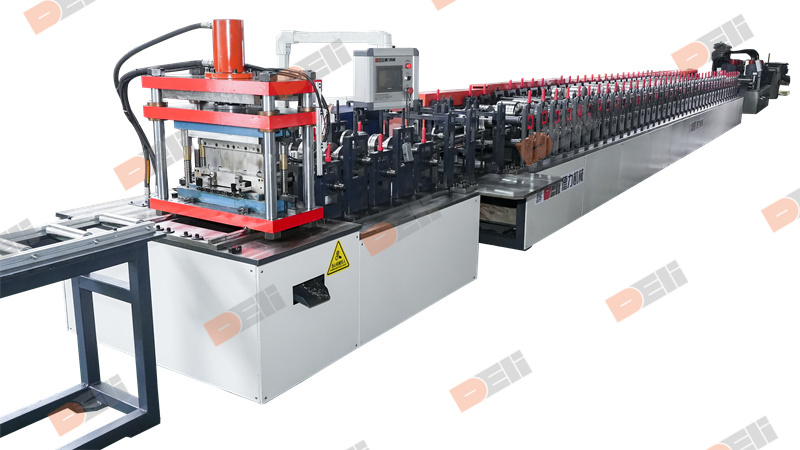

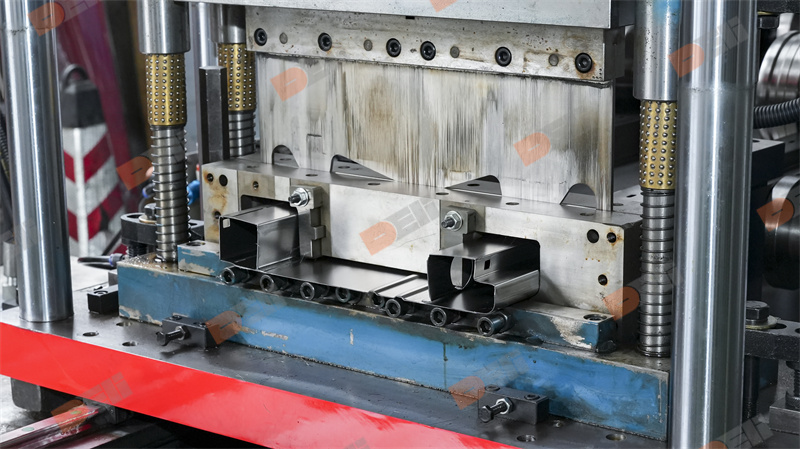

The storage rack shelf side panel roll forming production line can produce high-precision product with complex cross-section. It is capable of online butt welding on both sides, allowing for precise and efficient production of shelf panels. It can produce high-quality products with accurate dimensions and smooth surfaces.

The machine is ideal for manufacturers looking for high production efficiency and quality in the production of shelf side panels for various types of storage racking systems.

Features

1. High Efficiency: With online butt welding, the welding process is integrated with the forming process, which reduces the processing time and greatly improves the efficiency.

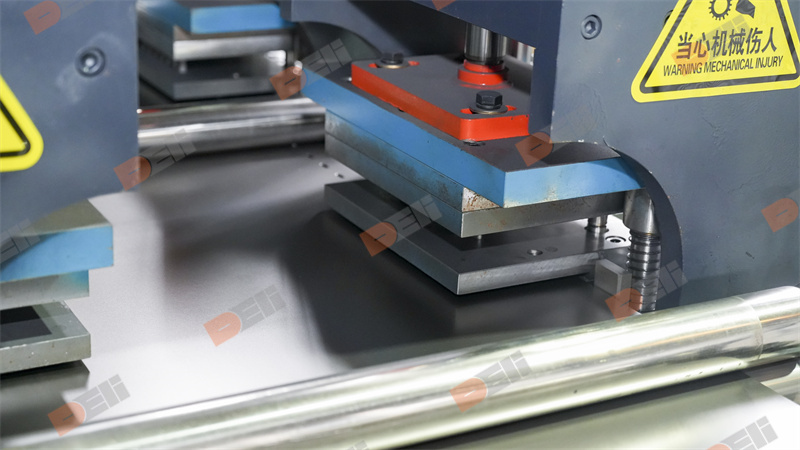

2. High Precision: The production line uses precise roll forming technique to ensure the accurate and consistent production of high-precision products.

3. User Friendly: The production line is easy to operate and maintain, friendly to all users even without professional qualifications.

4. Cost-Effective: The use of advanced technology and efficient production processes result in cost savings, energy saving, making the production line an economic choice for shelving panel manufacturing.

Production Process

Decoiling — Leveling — Pre-Punching — Roll Forming — Online Welding — Hydraulic Cutting — Discharge

Product Detail