The description of Drawer Slides Roll Forming Machine as a cold roll forming machine used specifically for manufacturing drawer slides highlights its specialized nature. The emphasis on higher performance and skill in profile forming distinguishes it from standard roll forming equipment, demonstrating the precision and expertise required in its operation.

The alternative names for this machine, such as “slide rail making machine,” “slide make machine,” and “telescopic channel roll forming equipment,” provide additional insight into its function and versatility, indicating its ability to cater to various types of drawer slide designs and configurations. These names also reflect the diverse terminology used within the industry to refer to this specialized machinery.

The manufacture of drawer slides has undergone a shift from traditional methods to the adoption of advanced roll forming technology. This transformation has significantly improved efficiency, precision, and quality control standards in the manufacturing process. Let’s explore how drawer slides are made, focusing on the role of roll forming machines in this innovative progression.

Slide Rail Definition

Slide rail, also known as guide rail and slideway, is a hardware connection part fixed on the cabinet body of the furniture for the drawers or cabinet boards of the furniture to move in and out. It is suitable for cabinets, furniture, briefcase, bathroom cabinets and other wooden or steel furniture drawer connection.

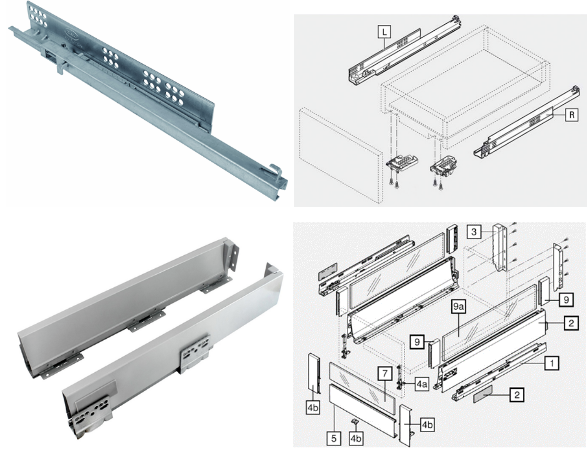

There are three types of slide rails that are most commonly used:

1. Roller type, such as powder coating slide rail. This type of slide rail has a relatively simple structure, consisting of a pulley and two rails. It has poor load-bearing capacity and does not have buffer and rebound functions. It is often used in computer keyboard drawers and light drawers.

2. Ball bearing type, such as telescopic channel ball bearing drawer slides. This type of slide rail is the most popular, mostly two-section or three-section metal slide rails, which are installed on the side of the drawer to save space. Ball bearing drawer slides in good quality can ensure smooth push and pull, large load-bearing capacity, and also have Soft Close or Push to Open functions.

3. Gear type, such as concealed drawer slide, tandem box drawer slide, etc. It belongs to the mid-to-high-end slide rail, the price is relatively expensive, and it also has the function of Soft Close or Push to Open, and is mostly used on mid-to-high-end furniture.

How Drawer Slides are Made?

As the main force of modern furniture, how is the telescopic channel ball bearing drawer slide produced?

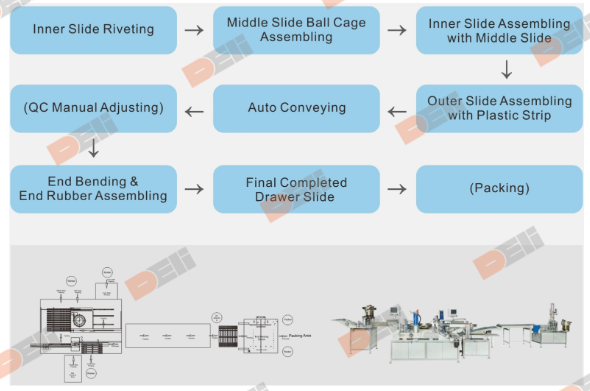

1) Semi-Automatic Assembly: outer/mid/inner slide roll forming (three units of roll forming machines), ball cage production (ball cage production line) → outer/mid/inner slide electroplating/electrophoresis → ball cage & steel ball & middle slide installation (middle slide ball loading machine) → outer slide lubricant grease added (outer slide oiling machine) → inner slide & top lock fixed with rivet pin (rivet machine) → steel ball pressing (ball pressing machine) → manual assembly of outer/mid/inner slide with plastic strip → quality inspection (three hand adjusters), outer slide end bending (end bending machine) → packaging (packing machine)

2) Fully-Automatic Assembly: outer/mid/inner slide roll forming (three units of roll forming machines), ball cage production (ball cage production line) → outer/mid/inner slide electroplating/electrophoresis → steel ball pressing (ball pressing machine) → fully automatic assembly (automatic assembly machine) → quality inspection (three hand adjusters) → packaging (packing machine).

Process of Slide Roll Forming

The manufacturing process of Drawer Slides Roll Forming Machine follows a fundamental flow comprising roll forming, punching, and length cutting.

In the roll forming process for drawer slides, a continuous strip of cold-rolled steel smoothly travels through upper and lower shaped rollers. Subsequently, this strip undergoes punching, embossing, straightening, and precision cutting. Straightening plays a crucial role in preventing material distortion or curling, ensuring the material adheres to the designated shape as per the original design. Roll forming lines are often equipped with specialized straightening mechanisms to guarantee flawless shaping that aligns with the desired specifications.

Every slide rail boasts unique design variations, necessitating customized production lines to accommodate specific profiles accurately. This implies that the production of different types of roll slides may demand distinct machinery or reconfiguration of existing setups. Consequently, developing these custom solutions requires considerable time and investment, particularly for intricate undermount drawer slides. Unlike the relatively straightforward contoured profiles found in roofing applications, slide roll forming relies on advanced manufacturing technologies.

One limitation of drawer slide roll forming equipment lies in the singular functionality of its rollers. Each set of rollers can only accommodate a single profile design, requiring replacements when manufacturing different types or models of drawer slide profiles. This factor can lead to substantial costs, especially for complex designs.