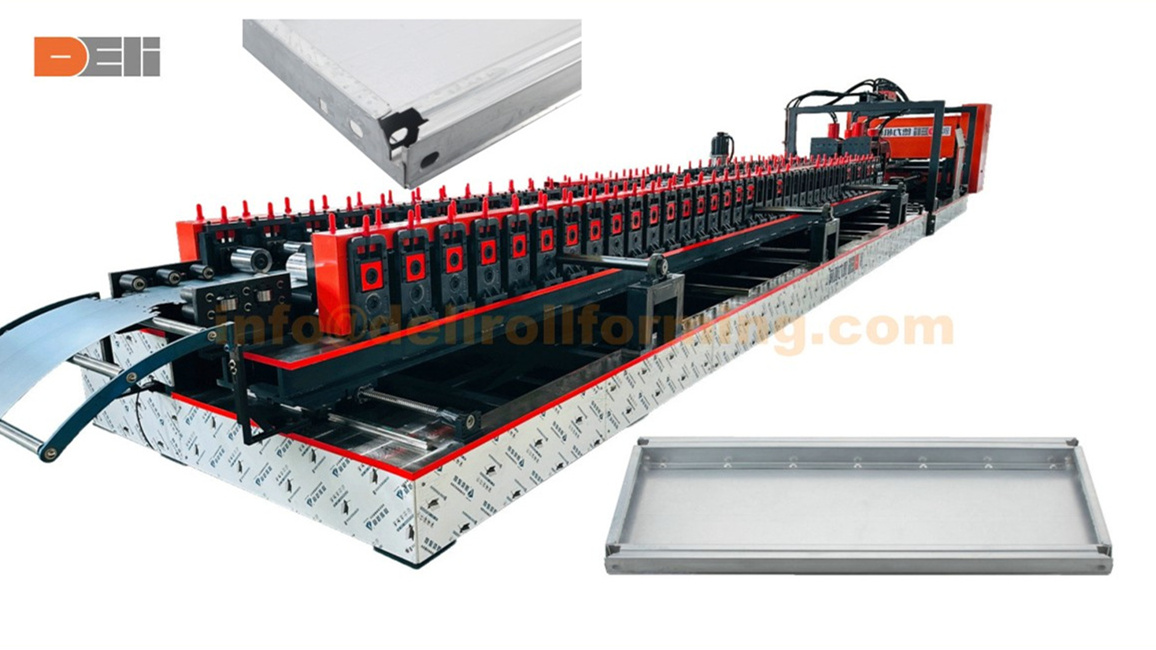

Product Description

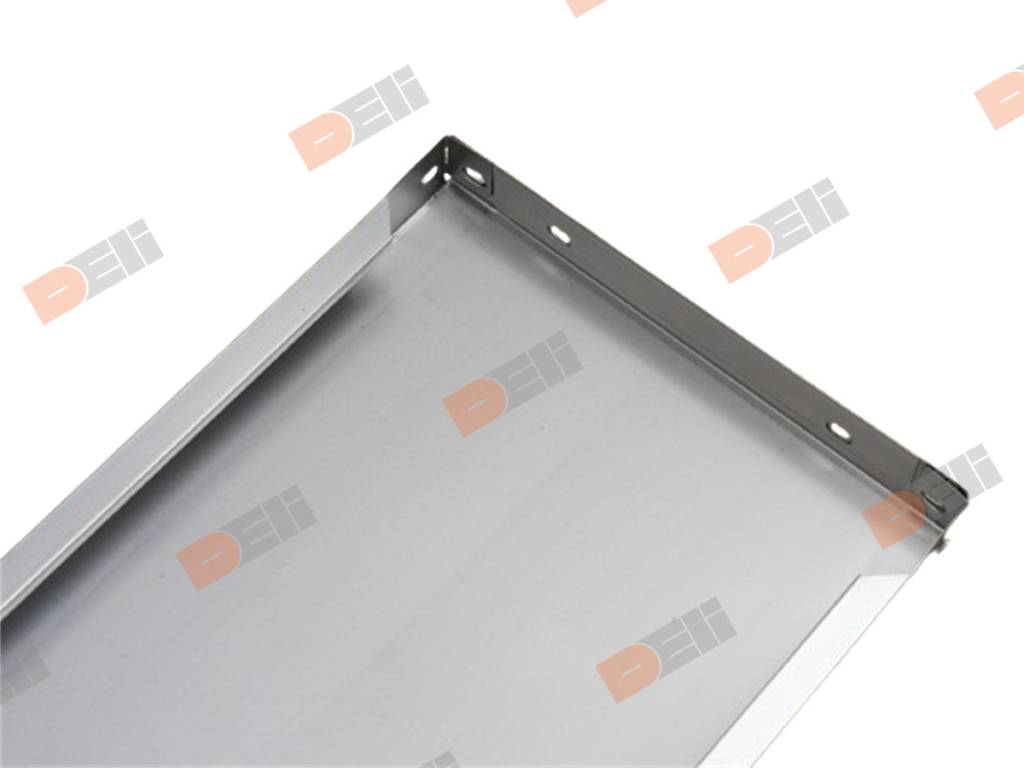

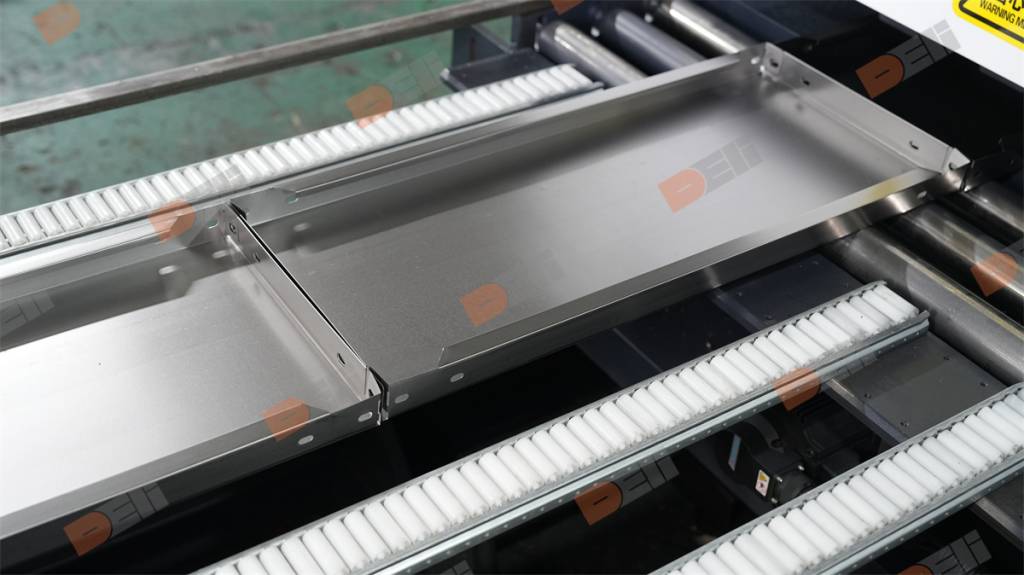

The automatic shelf board production line features online four-corner bending for increased efficiency and precision. The line is capable of producing high-quality, customizable shelving decking for a variety of applications. With its fully automated system, the production line can execute everything from material loading and unloading to precise folding and cutting. The four-corner bending feature ensures a tight fit on the rack, ensuring maximum stability and safety.

This production line is ideal for businesses in need of a cost-effective and efficient solution for producing high-quality shelving panels.

Features

1. Fully automated system

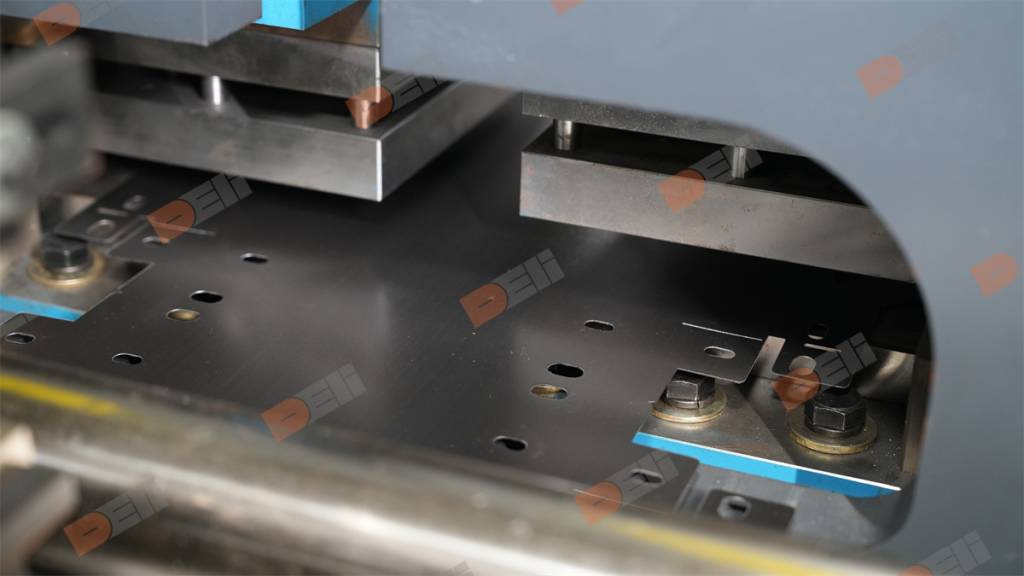

2. Online corner bending

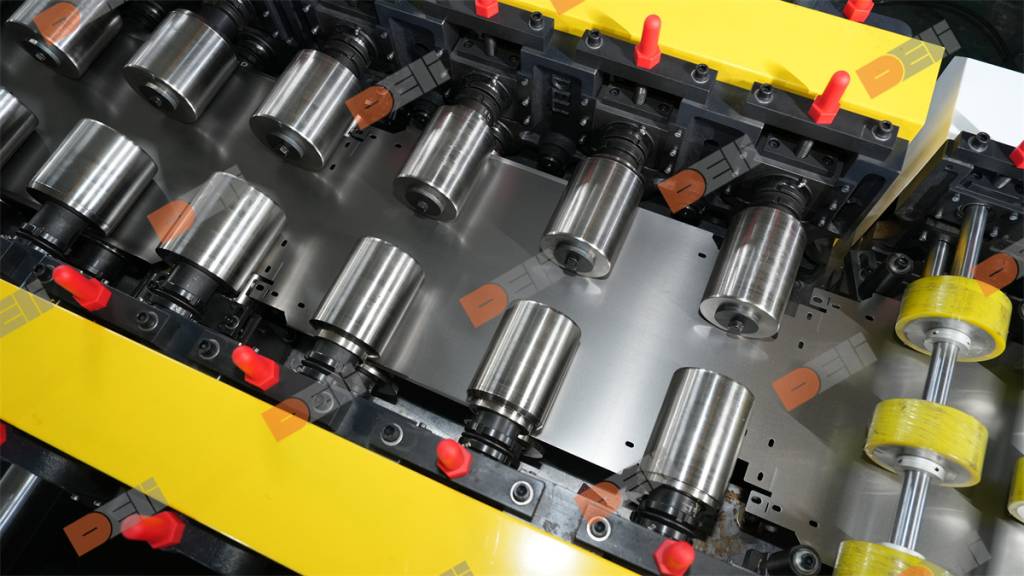

3. One-time forming

4. High efficiency and precision

5. High-quality production of shelf panels

6. Reduce labor costs and improve production capacity

7. Improve safety and reduce material waste

8. Easy to operate and maintain

9. Widely used in shelving and racking system industry.

Production Process

Decoiling — Leveling — Pre-Punching — Roll Forming — Inside Corner Bending — Cutting & Both Ends Bending — Discharge

Product Detail